ADDEV Materials is the authorised distributor of the AkzoNobel Aerospace Coatings range of high performance paints and coatings for civil and military aerospace applications. AkzoNobel Aerospace Coatings is the global leader in the manufacture, development and supply of coatings for the OEM and MRO sectors of the Commercial Airline, General Aviation and the Military Air markets. With manufacturing and support centres throughout the world, AkzoNobel Aerospace Coatings is considered the expert in their chosen field and is dedicated to providing innovative, reliable and efficient solutions to their customers worldwide. AkzoNobel Aerospace Coatings is a dedicated industry partner, providing support services including, training, technical advice and coatings consultancy.

ADDEV Materials is the authorised distributor of the AkzoNobel Aerospace Coatings range of high performance paints and coatings for civil and military aerospace applications. AkzoNobel Aerospace Coatings is the global leader in the manufacture, development and supply of coatings for the OEM and MRO sectors of the Commercial Airline, General Aviation and the Military Air markets. With manufacturing and support centres throughout the world, AkzoNobel Aerospace Coatings is considered the expert in their chosen field and is dedicated to providing innovative, reliable and efficient solutions to their customers worldwide. AkzoNobel Aerospace Coatings is a dedicated industry partner, providing support services including, training, technical advice and coatings consultancy.

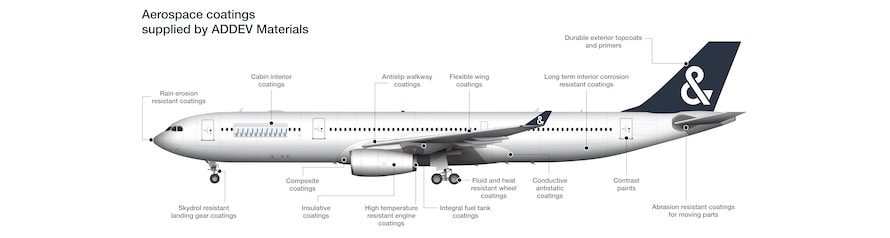

Applications:

In the manufacture of civil and military aircraft AkzoNobel coatings are approved and used by the World’s leading design authorities for all areas of the airframe for large and smaller airliners, fast jets, helicopters, transporters and in general aviation. In the maintenance (MRO) arena AkzoNobel produces coatings for application in service conditions for civil, military and general aviation.

Compliance and Sustainability:

AkzoNobel leads the industry in developing solutions which comply with current and future regulations. Low VOC versions of all types of product are available, which comply with EPA regulations including the European solvent emissions directive. The new REACh regulation will affect numerous substances including hexavalent chromates. AkzoNobel has an unrivalled range of chromate free primers for metal and composites including their patented Aerodur®2100MgRP magnesium based primer which offers galvanic corrosion protection to aluminium and Aerodur® HS2118 a high solids chrome free primer which can be used with and without pretreatment.

Technologies:

AkzoNobel has a leading position in coatings technologies for many important industrial markets. This technology base means that we can offer coatings chemistries including polyurethane, epoxy and acrylic in single and multi-component formulations; these can be delivered in water based and high solids materials.

Types of Coatings:

- Abrasion resistant coatings

- Anti-slip coatings

- Anti-static conductive coatings

- Basecoat/Clearcoat

- Cabin interior coatings

- Camouflage Coatings

- Composite Coatings

- Fuel tank coatings

- High Gloss Exterior Coatings

- High heat/insulation coatings

- Strippable systems

- Wing Coatings

| Selection of Official Approvals* | |

|---|---|

| Specification | Approved Coating |

| Structural Anti Corrosion Primers | |

| AIMS 04.04.001 / 003 / 038 / 040 / 042 | Aerowave® 2001, Aerodur® 37092 |

| BMS 10-11, Ty I, Cl A, Gr A | 10-P4-2 |

| Mil-PRF-23377 Type 1 | 10-P20-13 |

| Structural Topcoats | |

| AIMS 04.04.001 / 003 / 040 / 045 | Aerowave® 3003, Aerodur® 67348 |

| BMS 10-11, Ty II, Cl B, Gr D | 22 Series |

| BMS 10-60, Ty I and II, Cl B, Gr D | Eclipse® |

| Composite Coatings | |

| AIMS 04 04 002 | Aerowave® 2002, Aerodur® Barrier Primer 37045, 37076 |

| Fuel Tank Coatings | |

| AIMS 04 04 004 | Aerowave® 2001, Aerodur® 37092, 37035a |

| BMS 10-20, Ty II, Cl A, Gr A | 454-4-1 |

| AMS-C-27725, Ty I | 20-P1-21 |

| Exterior Durable Gloss Finishes | |

| AIMS 04 04 013 / 014 / 025 / 031 / 032 | Aviox® 77702 |

| AIMS 04 04 25 / 033 / 037 | Aerobase® |

| BMS 10-72 Type IX | Eclipse®, Aerodur® 3001 Basecoat/Clearcoat |

| AMS3095 | Aerobase®, Aviox® 77702, Eclipse® |

| Military/Camouflage Coatings | |

| Mil-PRF-85285 Type 1, MMS420, BSX34 | 58 Series |

| Mil-PRF-85285 Type 4, AIMS 04 04 036 | Aerodur® 5000 |

| SP-J-513-C-0083, Type III, Class A & B | Aerowave® 5001 |

| Chromate Free Anti Corrosion Primers | |

| MIL-PRF-32239 Ty II, Cl 1, Gr1 | Aerodur® 2100 MgRP |

| AMS3095 | Aerodur® 2100 MgRP, Aerodur® HS2118CF |

| AIMS 04 04 031 / 032 / 033 / 034 / 036 / 037 | Aviox® CF Primer 37124 |

| Cabin Interior Coatings | |

| FAR JAR 25.853 | Aerofine® |

*for extensive list of specifications follow this link http://aerospace.akzonobel.com/products

Pyroflex® 7 D 713

A 3-component polyurethane conductive coating for application to non-conductive substrates like composites:

– Matt black appearance.

– Resistance to aircraft fluids and chemicals.

– Surface resistance: R<50 K-ohm.