ADDEV Materials are the exclusive distributor for PM Research in the UK, Ireland, France and Spain. We hold a working stock of radomes, masks and tapes at our UK depot to minimise shipping costs from PM Research’s factory near New York.

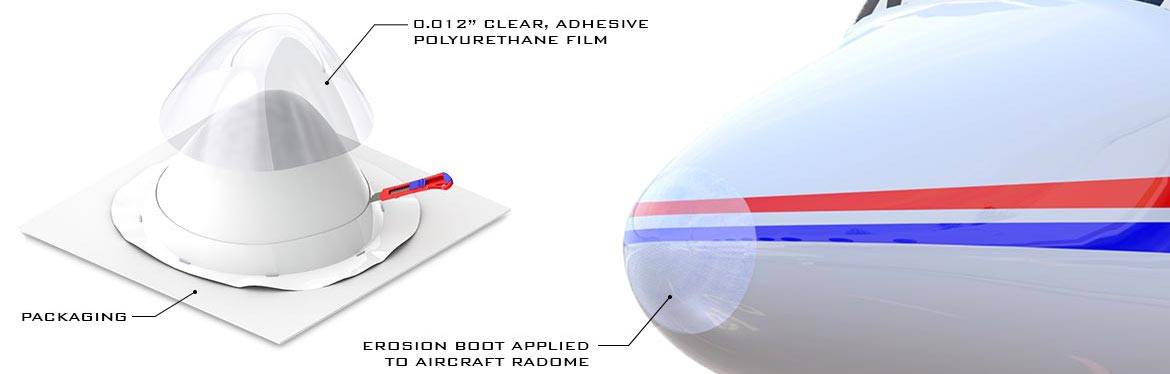

Erosion Boots

A little rain can cause extensive and costly erosion damage over time when you are flying at speeds of 200+ mph. This makes every leading edge of your aircraft highly susceptible to erosion, particularly the nose which commonly houses flight critical instrumentation. Our erosion boot is a thin, clear polyurethane film that acts as a protective barrier between your aircraft and the damaging elements. It’s been dubbed a boot because it is formed into a 3 dimensional shape that fits exactly over the complex contours of your aircraft leading edges. This ensures a perfect and streamlined fit every time, plus the ultra high-strength adhesive guarantees a secure installation for years and years of service!

Benefits:

- Protects your investment and saves you on costly down time and maintenance.

- Optimized thickness is virtually invisible to radar yet provides years of service.

- UV stabilized to eliminate yellowing over time.

- Extremely simple and easy to install.

- Nearly invisible after installation.

Leading Edge Tape

A clear adhesive 0.305mm (0.012″) thick polyurethane film is available in un-formed (straight) tape for erosion protection on any flat leading edge. Ideal for erosion protection on numerous aircraft leading edges including wing leading edges, horizontal tail, landing gear, etc. Also works great for many other applications including automotive erosion protection. Available in five different widths. 100 feet per roll.

Benefits:

- Clear adhesive 0.012″ thick polyurethane film. 100 feet per roll.

- Protect your investment and save thousands on costly maintenance.

- Optimized thickness is virtually invisible to radar and provides years of use.

- UV stabilized to eliminate yellowing over time.

- Extremely simple and easy to install.

- Nearly invisible after installation.

Antenna Masking

A selection of boots specifically designed for protecting aircraft antennas. Prevent erosion and reduce costly repair and degradation to your aircraft’s communication critical instruments!

Benefits:

- Protect your investment and save thousands on costly maintenance.

- Optimized thickness is virtually invisible to radar and provides years of use.

- UV stabilized to eliminate yellowing over time.

- Extremely simple and easy to install.

- Nearly invisible after installation.

Helicopter Radomes

A selection of radome erosion boots for helicopters. Protect helicopter radomes from erosion in normal flight as well as takeoff, landing, and low altitude hover where erosion from dust and other particulates suspended in the air becomes a greater concern.

Benefits:

- Protect your investment and save thousands on costly maintenance.

- Optimized thickness is virtually invisible to radar and provides years of use.

- UV stabilized to eliminate yellowing over time.

- Extremely simple and easy to install.

- Nearly invisible after installation.